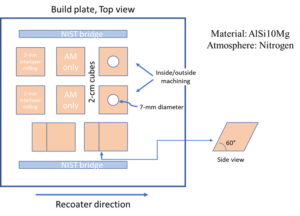

This project delves into the application of ultrasonic measurements to assess the microstructure characteristics of additively manufactured (AM) aluminum alloy AlSi10Mg samples fabricated through Laser Powder Bed Fusion (LPBF). LPBF creates components by selectively melting metal powder layer-by-layer, resulting in grains with elliptical morphology symmetric about the build axis under the cyclical heating and cooling process. Understanding the implications of such morphology on mechanical properties like strength and fatigue life is crucial. The spatially resolved acoustic spectroscopy (SRAS) will be employed for microstructure characterization to map localized wave speeds. This research explores nondestructive ultrasonic techniques to evaluate velocity, scattering, and morphology, comparing experimental data with theoretical models.