Capabilities and Equipment

Ultrasonics

- Conventional Ultrasonics

- Air Coupled Ultrasonics

- Nonlinear Acoustics

Laser Ultrasound

- Modeling – Propagating Fields

- Probe Modeling and Design

Acoustic Emission

Radiography

- Conventional X-ray

- CT/Laminography

Electromagnetic/Magnetic

- Eddy current

- ACPD

- Mag Particle

- Flux Leakage

Fluroescent Penetrant

Thermal and Sonic IR

Terahertz Radiation/FTIR

Ground Penetrating Radar

Microwave and Millimeter Wave

SHM

Center for Industrial Research and Service (CIRAS)

Probe Fabrication

- Ultrasound – nonlinear

- Strain/SHM

- Microwave

- Electromagnetic

X-ray Fee-Based Services

The fee-for-service micro-CT facility features a high-resolution computed tomography (CT) system equipped with micro-focus X-ray tubes, a 4-axis micro-step positioner, and a CMOS flat-panel detector. This allows both high-resolution (75 μm pixels) digital radiography and 3D CT to be performed.

CNDE provides researchers with X-ray and X-ray CT imaging data as a fee-based service. The internal ISU rate is $175 per hour. Client samples are scanned in the CNDE micro-CT system and returned with the associated 3D volume dataset. Additional post-processing of the 3D data set is available upon request and is subject to the same hourly rate of $175.

Select examples of CT scan output with post-processing can be found here.

Due to the complexity of performing CT scans on samples of differing sizes and compositions, the quality of the images and the final fee will vary. Please contact Scott Wendt for advice on viability and cost estimates.

Below are some representative costs:

- Initial X-ray CT scan & reconstruction post-processing (1.5 hours) ~$275

- High Resolution CT scan & reconstruction post-processing plus two-slice animations (2.5 hours) ~$450

- Other services available (all at an hourly rate)

- 2D X-ray Imaging

- CAD file from CT data

- Training on CT Data Analysis

- Dimensional Analysis

- Additional Animations

Typical deliverables include slice animations and a 3D volume dataset. Animations are always shared; other data, such as CAD files, will be shared upon request. The requestor must specify the format of the volume data set, which will be at least 0.5 GB in size. The total combined size of the data volume from one CT scan is over 10 GB.

PoC: Scott Wendt

Technical Assistance Program

The Center for NDE partners with the Center for Industrial Research and Service (CIRAS). One of the programs within CIRAS is the Manufacturing Extension Partnership; the Technical Assistance Program (TAP) of the effort assists Iowa manufacturers with various issues, including inspection and quality control and assurance. CNDE/CIRAS/TAP brings expertise in the field of nondestructive evaluation to Iowa industry.

Through this interaction, we assist companies by:

- Explaining & demonstrating the principles of various inspection methods

- Perform feasibility studies to determine if NDE methods will work for a given application

- Develop/Evaluate inspection procedures for old or new designs, and recommend new techniques

- Provide unbiased information on sources of equipment, NDT testing laboratories, and NDE advances

In short, we intend to help manufacturers become educated consumers of NDE products and services.

PoC: Chris Hill, 515-313-8251, chhill@iastate.edu

Equipment

Eddy current testing plays a critical role in ensuring the safety of energy supply systems and transportation, especially in the inspection of power plant and aircraft. For example, it is used to detect cracks in steam generator tubes and welds in nuclear power plants. In aircraft structures, tests are carried out around fasteners, in fastener holes and on aircraft engines parts. For jet engine maintenance, it is used to detect fatigue cracks in rotors and blades. CNDE owns and maintains laboratory facilities and equipment to conduct experimental research. Measurement systems are built around motion-controlled scanning systems, such as two XY-scanners and two multi-axis systems. The maximum of 8 degrees of freedom can be assembled to form a scanner system of linear and rotation stages in various combinations. The probe attached to the scanner can be connected to commercial eddy current instruments for data acquisition. The instrument output can be recorded by the computer in control, for examining the standard EC inspection. Or, for fundamental research, the probe is often driven and detected by laboratory-grade instruments such as impedance analyzer for high precision measurements. To meet the wide spectrum of research needs, CNDE maintains an array of instruments and probes, including commercial EC instruments and impedance/gain-phase analyzers, as well as network analyzers and combinations of function generators and lock-in amplifiers.

Ultrasonic testing (UT) forms a large part of the work produced by CNDE and includes modeling of propagating wave interactions with microstructural features and flaws, materials characterization measurements, transducer design and characterization methods and development and testing of novel inspection approaches for difficult materials and geometries. Methods deployed at CNDE include standard contact and immersion measurements and inspections, as well as air-coupled and laser UT approaches. Additional techniques include nonlinear acoustics (harmonic generation) and nonlinear resonance ultrasound spectroscopy (NRUS) for materials characterization.

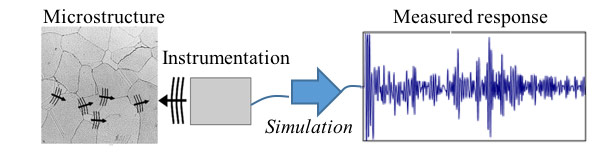

Modeling efforts for strain waves includes interactions with various metal alloy grain morphologies, size distributions and texture/grain alignment conditions. Materials characterization measurements allow prediction of microstructural conditions through attenuation and grain scattering measurements, and transducer design and characterization affords selection and application of the most appropriate material probing equipment and conditions. Standard contact and immersion inspection constitute the bulk of materials characterizations and flaw detection work, where air-coupled and laser UT inspections are introduced when conditions require non-contact approaches.

Nonlinear methods have seen limited use outside the laboratory but offer significant sensitivities beyond standard linear approaches. However, with the increased sensitivity comes increased complexity and a more limited application space. Efforts at CNDE aim at simplification and standardization of nonlinear measurements so to allow inversion of results for the prediction of material properties.

The efforts at CNDE remain focused on increasing the utility, sensitivity, and economy of ultrasonic inspection approaches for the continued evolutions in engineering materials and their applications.

Materials/Microstructure Characterization

Ultrasonic measurements of acoustic velocities in engineered materials allow the determination of many of the material parameters used in design, including elastic moduli (Young’s, bulk, shear, etc.), Poisson’s ration and the higher order elastic constants. With additional work, acoustoelastic constants can be measured that provide determination of ultrasonic velocity changes with stress/loading.With more careful and complex measurements of directionally and frequency dependent scattering, microstructural features such as grain sizes, shapes and orientations can be elucidated ultrasonically. This capability was largely developed by Dr. Bruce Thompson and a cadre of modelers and experimentalists, both CNDE staff and graduate students, throughout the 1980’s and 1990’s. The legacy of that work is an assortment of measurement models, procedures and processing codes that produce the so-called Figure-of-merit (FOM), a frequency dependent parameter relating the scattering potential of a given microstructure. The key utility of FOM is that with a measure of the scattering potential combined with the flaw scattering models also developed, signal to noise ratios can be estimated for material inspections as well as inputs for probe designs for specific applications. In turn, one could then estimate the smallest defect of a given flaw model type that could be reliably detected (above the background grain noise level). These tools today are continuously being revised and tested, deployed and evaluated on current issues in the inspection community, such as micro-textural regions (MTRs) in Titanium alloy aero components.

PoC: R. Roberts and D. Barnard

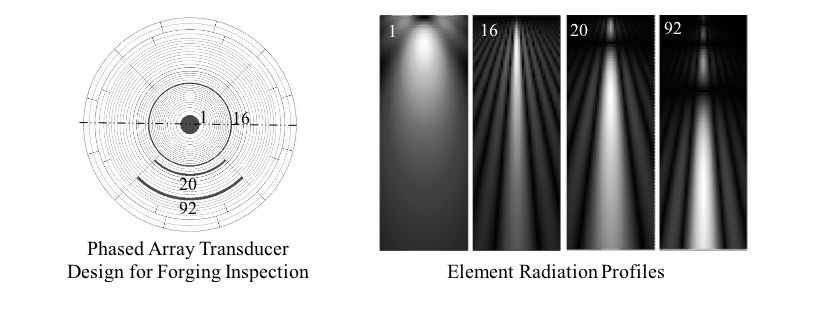

Probe Characterization and Design

The key to providing insight into microstructure feature dimensions, such as grain size, is an understanding of the ultrasonic probe radiation field. Whether an unfocused planar or focused probe, measurements of radiating field strength in 2 and 3 dimensions allow determination of the probe active diameters and geometric focal lengths. Additional measurements of the pulse volume along with the grain noise modeling and flaw modeling allow optimizing probe designs to maximize sensitivity to small flaws in thick, noise, or highly attenuative materials.

PoC: R. Roberts and D. Barnard

Modeling

From the beginning, CNDE has been at the forefront of NDE measurement model development. As NDE modeling software obtains widespread acceptance, CNDE continues to lead in the modeling of ultrasound measurement physics. Computer simulation enables the design of NDE inspections (probe optimization, scan configuration, data collection, and processing) in complex geometries previously deemed uninspectable within a fraction of the legacy time and cost. The ability to design inspections in highly anisotropic materials (fiber-reinforced composites, single crystal alloys) depends on the availability of computational models to reveal the complicated physics of energy transport in these materials. A more subtle definition of flawed material state implies sensing correspondingly subtle differences in material parameters (e.g., mean grain size or orientation). Computational simulation of measurement response is essential for the quantification of measurement dependence on such parameters. Beyond the design of NDE inspection, computational NDE simulation plays an important role in engineered lifecycle management by functioning in concert with material performance and degradation models to provide a physics-based high-confidence system deployment.

CNDE’s strength in NDE simulation lies in its ability to generate computational models from first principles, custom designed to address unique inspection challenges that fall outside the capabilities of commercially available software. Ongoing CNDE research is developing models for complex heterogeneous materials (aerospace alloys, composites, additive manufacturing) that quantify the dependence of measured response to material properties and defect parameters. Capabilities to simulate and optimize inspection instrumentation (phased arrays, complex scanning) enable effective inspection of increasingly complex geometries and materials. Importantly, reflecting its roots as an industry laboratory, CNDE is experienced in industrial collaboration to bring these capabilities to bear on current industry-critical inspection problems.

PoC: R. Roberts

PoC: R. Roberts

Nonlinear Acoustics

Nonlinear acoustics at CNDE primarily focuses on two measurement approaches: generation of second harmonic content in pulse-echo and through-transmission scenarios and nonlinear resonance ultrasound spectroscopy (NRUS). Second harmonic generation (SHG) has the potential to be a highly sensitive modality for evaluating subtle changes in metal microstructures as a result of thermal degradation and early fatigue damage. However, the technique is not easily applied in the field, and absolute measurements of the nonlinear effect are the best option for inversion of the resulting response to provide insight into specific microstructural changes or conditions.At CNDE, efforts in SHG have concentrated on the procedures involved in the measurements, including the probe calibrations necessary for absolute measurements. To this end, significant simplifications have been made to the calibration for planar contact probes coupled to samples of interest, and the calibration has been extended to immersion probes. This extension is a necessity if simplified scanning is ever to be a useful approach in inspections. With calibrated immersion probes, the nonlinearity of the immersing fluid can be measured and accounted for, and in this way, allow nonlinear through transmission immersion scanning. This approach is in the process of development, testing and evaluation.NRUS will not, in general, ever be a true fieldable nondestructive evaluation modality. However, it has proven useful in elucidating the nonlinear response of various materials (metals, ceramics, composites) in various conditions (aging heat treated, quenched, fatigued, local plastic deformation, etc.). CNDE has assembled a relatively low cost accelerometer-based NRUS measurement (compared to the laser interferometer approaches) that has demonstrated significant utility, ease of use and sensitivity for evaluating the nonlinear response of materials. Continued development is underway.

PoC: D. Barnard

Air-coupled ultrasound is an outgrowth of the need for non-contact (and non-immersion) ultrasonic inspection and is particularly useful in polymer composite materials. In general, the frequencies used are limited to the range of 50kHz to 1MHz because the attenuation in even short paths in air is quite high. With the lower frequency comes longer wavelengths and, hence, a decrease in spatial resolution. However, the high attenuations typically seen in polymer composite materials are easier to overcome at the lower frequencies used in air-coupled approaches.

Generation of all manner of lamb and surface waves are possible with air-coupled ultrasound without the need for wedges, and these modes, as well as longitudinal and shear modes, have been deployed to detect interlayer delaminations, skin-to-core disbonds and impact-damaged crushed cores (in honeycomb sandwich constructions), fiber waviness (marcels) and dry-fiber/resin starved regions in resin transfer molded parts as small as fairings and as large as wind turbine blades.

PoC: D. Barnard

The research into Laser-based ultrasound at CNDE is largely focused on adapting the technology to production environments. Thus far, our primary focus has been on optimizing it for the detection of defects during 3D printing of metal parts. Since the feature size of these parts is less than a hundred microns, we have focused on reducing the inspection dimensions from standard approaches requiring ~1 mm to only needing 20 to 50 um. CNDE has numerous tools to optimize laser-based ultrasound for additive manufacturing and other emerging machining technologies.

CNDE utilizes COMSOL finite-element simulations that capture the coupled physics between the laser-induced thermodynamics and the resulting acoustic vibrations. Complete 3D models can be simulated for modest-sized geometries. In addition to our modeling resources, CNDE also has an inventory of laser ultrasound generation sources and detectors that cover a range of power levels, spot sizes, and sensitivities, with the ability to couple these components to multi-axis scanning stages.

POC: M. Subair

Research Areas and Project Support

The research facilities include high-resolution computed tomography (CT) with a micro-focus X-ray tube, a 4-axis micro-step positioner, and a CMOS flat panel detector that allows both high-resolution (75 μm pixels) digital radiography and 3D CT to be performed.

High-speed CT reconstruction algorithms convert raw data acquired into 3-D volume data sets.

Open-source image analysis software is available for visualizing 2D and 3D data sets.

Real-time radiography can be accomplished using X-ray systems and flat panel digital detectors in static or streaming mode.

The suite of X-ray inspection techniques is complemented by an X-ray simulation capability, which provides unique analysis tools for evaluating the effect of various parameters on image quality.

Through collaborations with the Department of Mechanical Engineering, we also have access to a real-time stereographic imaging system composed of two 200 kV X-ray tubes and two 16-inch diameter image intensifiers.

Our laboratory resources include:

- MicroCT Lab

- Three microfocus X-ray sources for high-resolution X-ray imaging

- 3D high-resolution Computed Tomography with 10 μm spatial resolution or better

- Dual-energy X-ray Detector

- Image Analysis Lab

- Computed Tomography reconstruction and 3D volumetric data integration and visualization

- X-ray radiography simulation software (XRSIM)

PoC: S. Wendt

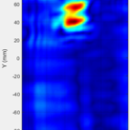

The thermography research group at Iowa State University Center for NDE has parallel flash- and vibro-thermography programs. Our goal is to advance the state-of-the-art in thermographic nondestructive testing through basic scientific research. Our primary current efforts are focused around vibrothermographic nondestructive testing. Vibrothermography, also known as “thermosonic,” “sonic infrared,” and “Sonic IR,” involves exciting a specimen with vibration and looking for heat generated at cracks. A piezoelectric stack generates the high-amplitude vibration, and the specimen is imaged with an infrared camera to see vibration-induced heating of cracks and flaws in the material. Current theory suggests that the heat is generated by frictional rubbing between crack faces. Our research group works simultaneously to understand crack heating and vibration better and develop improved measurement apparatus and experimental procedures.

Flash thermography finds delaminations in composite materials by how they block heat flowing from an initial pulse. Vibrothermography (Sonic IR) finds cracks in metals and delaminations in composite materials by detecting frictional heating of rubbing flaw surfaces. We have unique capabilities for both modalities derived from our custom reconfigurable instrumentation. We can use innovative heat/vibration sources and integrate innovative analysis. In flash thermography, we have introduced the use of model-based inversion to interpret hidden subsurface structures. Our focus on vibrothermography (Sonic IR) has been on studying the underlying physics of the crack heating process and developing a model (VibroSim) to predict the capability and reliability of vibrothermography crack detection.

Vibrothermography image of a turbine blade, analyzed with ISU-developed image sequence processing.

PoC: S. Holland

Microwave and millimeter waves occupy the frequency spectrum covering ~300 MHz-30 GHz and 30 GHz-300 GHz, corresponding to wavelengths (in air) of 1000-1 mm, respectively. Materials interact with these waves in ways that make them extremely useful for certain nondestructive testing and evaluation (NDT&E) applications. Although initially considered under the category of “emerging technologies”, much has taken place in advancing microwave and millimeter wave NDT&E techniques over the past three decades. As such, microwave nondestructive testing was recently recognized and designated by the American Society for Nondestructive Testing (ASNT) as a “Method” on its own. The unique features and capabilities offered by these techniques, and the sustained R&D efforts in this area over several decades, have brought these techniques to the forefront of NDT&E science, engineering, and applications. These features include:

- ability to penetrate dielectric (electrically nonconductive) materials,

- high sensitivity to detecting small flaws, as a result of relatively small wavelengths and large available signal bandwidth,

- coherent properties of the waves, allowing for the use of signal amplitude and phase, in addition to wave polarization,

- one-sided and non-contact measurement capabilities (i.e., no need for couplants),

- sensitivity to surface properties of metals and carbon composites,

- non-ionizing nature of the waves, and

- relative ease-of-use.

Examples of recent successful investigations and developments using microwave and millimeter wave techniques include:

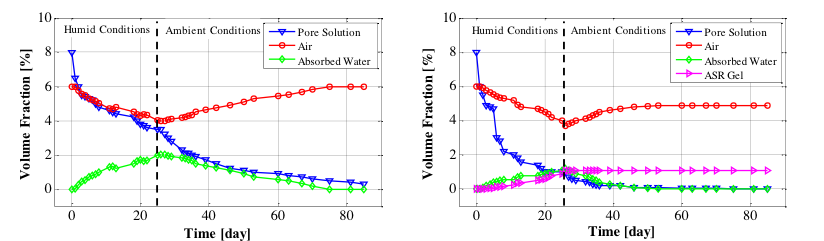

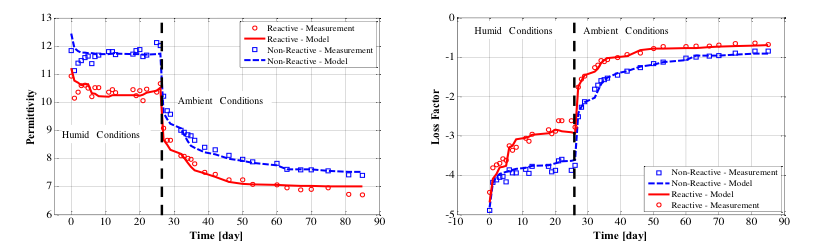

- Comprehensive materials characterization (e.g., porosity, mixture content, etc.) and chemical reactions such as cure-state monitoring in various chemically-produced materials (i.e., resin binder, rubber, etc.).

- resin cure-state.

- Inspection of complex dielectric composites and layered structures made of polymers, ceramics, thermal barrier coatings, radomes, etc.

- Porosity estimation in composites and ceramics such as thermal barrier coatings and composite skin subjected to loading (i.e., aircraft radome skin),

- Fatigue crack detection and characterization on metal surfaces, using several novel methods.

- Detection and evaluation of surface anomalies (e.g., scratches, impact damage) in metals and carbon composites.

- Comprehensive materials characterization of cementitious materials chemical and physical properties including chloride permeation and alkali-silica gel reaction (ASR) detection and evaluation.

- Development of hybrid measurement technique using embedded modulated scattering PIN diode-loaded dipole antenna for material characterization and microwave imaging,

- Near-field high-resolution imaging.

- Real-time, 3D, portable, battery-operated and high-resolution imaging.

- Frequency-modulated continuous-wave (FM-CW) radar for short-range applications such as detection and evaluation of flaws in composite structures (e.g., walls).

- Microwave and millimeter wave noninvasive diagnosis of human skin for cancer and burns.

PoC: and M.T. Al Qaseer and M. Dvorsky

Several examples of various applications and results are provided below.

Section of fiberglass pipe joint (left), X-ray image showing lack of adhesive at the joint (center) and millimeter wave (Ka-band, 26.5-40 GHz) SAR image (right). Sample Courtesy of Fiberglass Structural Engineering, Inc.

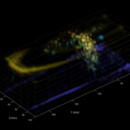

Millimeter Wave (26.5-40 GHz) 3D SAR image of a thick HDPE sample with porosity. Sample Courtesy of NDT Innovations, Inc.

Aircraft radome mimic, map of interior flaws, near-field image (using open -ended waveguide) at 33 GHz and near-field image (using open -ended waveguide) at 73 GHz.

Portable real-time SAR imaging system for inspecting cylindrical pipes (left), PVC pipe with internal damage (center), and microwave SAR image of the damage (right).

Portable, real-time, high-resolution 3D Microwave Camera, with a size of ~260 mm x 210 mm x 180 mm and a weight of 4.8 Kg (left) and most recent handheld real-time Microwave Camera based on Chaotic Excitation Synthetic-Aperture Radar (CESAR), with a size of ~140 mm x 89 mm x 55 mm (right).