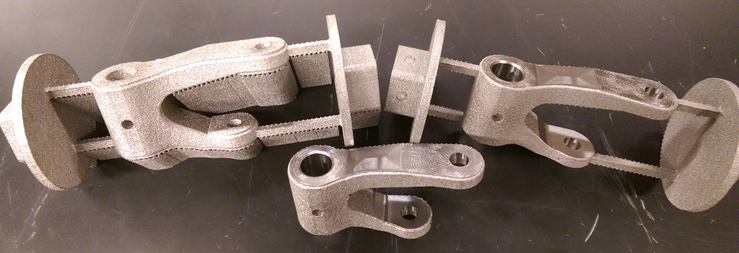

The importance and impact of Additive Manufacturing (AM), spanning almost all national and global industrial manufacturing processes cannot be overestimated. The ability to rapidly and reliably manufacture parts and components has transformed the way we currently look at manufacturing enterprise. Additive manufacturing however desirable, brings with itself significant inspection challenges of manufactured parts that take a plethora of shapes, geometries, sizes and properties (e.g., metals, ceramics, polymer-matrix composites, etc.).

In this respect, the following excerpts from a recent report entitled – Rapid Reliability Assessment of Safety-Critical and Emerging Technologies: Next Generation Nondestructive Evaluation1, succinctly describes the challenges facing AM and four identified key areas in which focused research is needed to overcome these challenges.